Portaspec spectrometer sales video

- 1970s

These captions and transcript were generated by a computer and may contain errors. If there are significant errors that should be corrected, please let us know by emailing digital@sciencehistory.org.

Transcript

00:00:00 ♪♪

00:00:10 ♪♪

00:00:20 ♪♪

00:00:30 ♪♪

00:00:40 Flight 535, non-stop service for Chicago's O'Hare Field, is now boarding at gate 27.

00:00:52 Welcome to flight 535, sir.

00:00:55 Thank you.

00:00:56 Oh, excuse me, sir, but I don't believe that both of those cases will fit under a seat.

00:01:00 No, they won't, but don't worry about that.

00:01:03 The small case is designed to fit under an airline seat, and the large one has its own seat.

00:01:07 You bought a ticket for it?

00:01:08 Well, I don't normally, but I have to make a fast connection in Chicago.

00:01:12 No time for baggage.

00:01:13 They must be very important.

00:01:15 Well, they're important for my job.

00:01:16 And what's that?

00:01:17 I'm a field service representative for a steel company.

00:01:20 Well, we're about to take off now. Enjoy your flight.

00:01:24 Thanks.

00:01:25 ♪♪

00:01:44 Just what do you have in those cases?

00:01:47 An X-ray spectrometer.

00:01:49 Oh, the large one must be the power supply, right?

00:01:52 Sure, take a look.

00:01:53 Say, uh, you seem to know something about this.

00:01:55 Oh, sure.

00:01:56 I used to be an X-ray technician, but you know the lure of travel.

00:02:00 Right.

00:02:01 But this is no normal X-ray, is it?

00:02:03 No, it's not.

00:02:04 Let's see, here's a manual with a picture of it.

00:02:07 It's a Pitchford Scientific Portaspec, a portable spectrometer.

00:02:11 The large unit is a 30 kilovolt power supply, and the small one is called the probe head.

00:02:16 And it takes the picture?

00:02:17 No.

00:02:18 In fact, this device doesn't use X-rays to take pictures.

00:02:21 It uses them to determine what chemical elements are in materials.

00:02:25 But it is like a medical X-ray in that it doesn't harm the sample.

00:02:28 It's called a non-destructive test.

00:02:30 How does it do that?

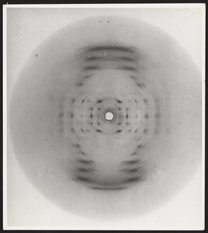

00:02:31 Well, the process is based on the fact that any element, when bombarded by X-rays, will fluoresce.

00:02:37 That is, it will emit X-rays of its own.

00:02:39 And the interesting thing about these secondary X-rays is that they will be of a particular wavelength,

00:02:46 or set of wavelengths, and that they will always be characteristic of that element and no other.

00:02:52 So the Portaspec uses those wavelengths to determine the presence of a certain element.

00:02:57 Presence and concentration.

00:02:59 Right.

00:03:00 But how does it differentiate between those various wavelengths?

00:03:03 I was afraid you were going to ask that.

00:03:05 Okay, here's an interior view of the probe head showing the X-ray tube housing.

00:03:10 The X-ray tube is positioned to emit X-rays downward through a window.

00:03:14 These primary X-rays bombard the sample, causing it to fluoresce.

00:03:18 And its atoms emit secondary X-rays in every direction, huh?

00:03:22 Right.

00:03:23 And many of them enter a collimator, which only allows parallel rays to pass.

00:03:28 So now we're dealing with parallel X-rays of differing wavelengths.

00:03:32 Exactly.

00:03:33 Now it so happens that there are certain crystals which reflect X-rays at angles that vary with respect to their wavelengths.

00:03:41 Oh, and I'll bet there's one of those crystals right in the path of our parallel secondary X-rays.

00:03:46 That's right.

00:03:47 It's made of lithium fluoride 200, and it's the heart of the Portaspec's goniometer,

00:03:52 which is a fancy term meaning angle measurer.

00:03:54 But to measure the amount of X-radiation at a particular angle,

00:03:58 you'd have to screen out the rays reflected at other angles.

00:04:01 And that is done by a second collimator.

00:04:03 I see.

00:04:05 Leaving the second collimator, the uniform wavelength X-rays enter a detection cell where each one is counted.

00:04:13 Giving both a qualitative determination...

00:04:16 By measuring the angle of reflection...

00:04:21 And a quantitative determination...

00:04:24 By the actual count of the X-rays entering the detection cell.

00:04:28 Exactly.

00:04:29 Isn't that a lot for one instrument to do?

00:04:31 It sure is.

00:04:32 Especially a portable instrument like this one.

00:04:34 What kinds of material does it analyze?

00:04:36 Anything I might be familiar with?

00:04:38 Oh, yeah.

00:04:39 Everything around you.

00:04:40 The plastics in the upholstery.

00:04:43 And covering the windows.

00:04:46 The metal in the skin of the airplane.

00:04:49 And more importantly, the turbine blades in the engines that are keeping us in the air right now.

00:04:54 Say, you do some pretty important work, don't you?

00:04:57 Sometimes.

00:04:58 Sometimes?

00:04:59 Actually, this instrument is most frequently used to check the quality of incoming materials for manufacturing.

00:05:05 And to distinguish between grades of materials in the field.

00:05:08 I guess it's important to know those things.

00:05:10 But what about safety?

00:05:12 I know in medical X-ray we were always concerned with shielding and safety.

00:05:16 Well, of course the operator of a Portaspec must be concerned with safety also.

00:05:20 But Pitchford Scientific has gone to great lengths to ensure the safety of this instrument.

00:05:25 For instance, many X-ray spectrometers use atomic radiation from radioisotopes to excite the sample atoms into X-ray fluorescence.

00:05:32 Those devices can't even be mailed, much less transported in an airliner.

00:05:37 But since the Portaspec uses an X-ray tube source, it's entirely radiation-free when it's not in use.

00:05:43 And when it is in use, all the primary X-ray energy exits through the sample port.

00:05:48 And any sample pressed up against the port blocks the X-rays from the outside.

00:05:53 A switch located next to the port allows the X-ray tube to be energized only when a sample is present.

00:05:59 This instrument even comes equipped with adjustable metal shoes, which butt up against round stock to protect the operator from any X-radiation.

00:06:07 Also, when it's used with a sample holder, the holder fills the port.

00:06:12 Oh, it's upside down.

00:06:14 Right. It can function in the inverted mode for analyzing liquids and powders using these plastic cups.

00:06:20 And even then the sample holder shields the operator.

00:06:22 And even so, he wears a film badge that will indicate if he has received any X-radiation.

00:06:27 Well, that certainly is reassuring.

00:06:29 And there are other safety features too.

00:06:31 For instance, a special ground circuit that won't allow it to operate unless a good solid ground is established.

00:06:37 A key lock on the probe head to eliminate the chance of the device being operated by unauthorized personnel.

00:06:42 And a fail-safe X-ray on light, which lights up to inform the operator when X-rays are being produced.

00:06:49 And which won't allow the X-ray tube to operate if the light is burned out.

00:06:53 Well, it sure must be safe to operate.

00:06:56 But the samples we've seen, tubing, rod, plate, are pretty uniform.

00:07:01 Suppose I wanted to analyze samples that come in unusual shapes.

00:07:05 Well, when you're going to make a determination, you've got to be sure that the sample is in an appropriate format.

00:07:11 It just happens that the company that makes the Portaspec...

00:07:14 Pitchford Scientific Instruments?

00:07:16 They also produce sample preparation equipment.

00:07:19 Suppose your sample is comprised of, say, mill cuttings.

00:07:22 You can't very well hold them under the sample window by hand.

00:07:25 So you need a method for melting the cuttings into a format appropriate for analysis.

00:07:30 For this, you can use the Pitchford Electric Arc Button Furnace.

00:07:34 The furnace uses the power from a DC electric arc welder to melt the cuttings into a quarter inch thick button, an inch and a quarter in diameter.

00:07:42 This thing is great.

00:07:43 It takes less than a minute, and the violence of the electric arc provides its own stirring action to assure a homogeneous sample.

00:07:50 So then you're ready to test, right?

00:07:52 Well, yeah, unless you want to make a very precise quantitative analysis.

00:07:57 Then you'd want to make the surface of the button, or whatever else you wanted to test, flat and smooth.

00:08:02 And for that, you'd use a precision surface grinder.

00:08:05 Made by Pitchford Scientific.

00:08:07 Right.

00:08:08 You might get the idea that I think those guys know what they're doing.

00:08:11 Anyway, you'd use this surface grinder to make the face of the sample uniform, which makes for an analysis that's very accurate and repeatable.

00:08:19 Now, if the sample is an ore, or anything else that can be ground into a powder,

00:08:23 Pitchford Scientific offers the Pica Blender Mill, which uses tungsten carbide balls in a grinding cylinder to pulverize the material.

00:08:31 So it can be placed in special cups for analysis, which is very convenient.

00:08:35 That's pretty simple.

00:08:37 Sure, but again, for a very accurate determination, more precision is required.

00:08:41 In which case, you would want the uniform particle size grinder,

00:08:45 which, through a patented process, actually forces the particles out of the grinding chamber as soon as they have been ground to the proper size.

00:08:53 So, now I've prepared my sample.

00:08:56 How do I go about making the determination?

00:08:58 Well, first you want to establish a standard.

00:09:01 To do that, you place the iron standard that comes with the instrument in the sample drawer.

00:09:05 Then, slide the drawer into the sample holder, which places it under the port in the probe head.

00:09:10 Closing the door on the sample holder energizes the x-ray tube.

00:09:14 Or, if you have some iron bar stock, or tubing, or plate handy,

00:09:21 you can set the probe head down on it and energize the x-ray tube by pushing the x-ray on button.

00:09:28 Then you'd set the goniometer with the selector arm so that the element dial reads 57.52 degrees.

00:09:34 That's the two theta angle, at which the wavelength of iron's characteristic x-ray emission is diffracted by the lithium fluoride 200 crystal.

00:09:41 Two theta?

00:09:43 Sure. Theta is the designation of the angle of x-rays incident on the crystal.

00:09:48 Two theta is the angle at which they are reflected.

00:09:51 So, as I adjust the selector arm to other positions, I can read that two theta angle,

00:09:58 and the name of the element, directly from the dial on top of the probe head.

00:10:03 Isn't that something?

00:10:04 It sure is. But you said that some elements fluoresce at more than one wavelength.

00:10:09 Do they ever interfere with each other?

00:10:11 Well, some do. But there's an interference chart that comes with the instrument that straightens out any of those conflicts.

00:10:17 So now I can determine the presence of any of 62 elements.

00:10:21 How can I quantify those determinations?

00:10:23 You do that by comparing the number of counts per unit time you get from standards of the element you want to analyze

00:10:29 to the number of counts you get from your sample.

00:10:31 I see. I can plot a curve with percent concentration on one axis and counts per unit time on the other.

00:10:38 But isn't there some way to just analyze a sample for everything?

00:10:41 There sure is. The Portaspec can be fitted with a goniometer drive motor,

00:10:46 which will move the goniometer through its full scale at a constant rate of two degrees two theta per minute.

00:10:52 You can just connect the output of the instrument to a 100 millivolt strip chart recorder,

00:10:57 and the recorder will generate a graph.

00:10:59 And the recorder will generate a graph indicating the rate of counts at every angle.

00:11:04 So the chart will show what elements are present by where the peaks occur angularly.

00:11:09 And their concentration by the heights of those peaks.

00:11:12 That's really something.

00:11:13 Oh, by the way, when the Portaspec is operated that way, or any time it's used fairly continuously,

00:11:19 it should be connected to a water supply for cooling or to a portable recirculating water cooler,

00:11:24 which is also available from Pitchford Scientific.

00:11:27 There must be thousands of uses for an instrument like that.

00:11:30 Literally thousands. And the applications start with the most basic raw materials

00:11:35 and go right on through the most sophisticated and intricate processes of modern technology.

00:11:40 How do you mean?

00:11:41 Well, for example, the Portaspec is used in mines to determine how much useful material is in a sample of ore.

00:11:47 That's pretty basic.

00:11:48 Or metallic impurities in crude oil.

00:11:50 And that's pretty important.

00:11:52 Especially these days.

00:11:54 And we've already talked about incoming materials identification.

00:11:57 Producers of metals, for instance, have to know how rich the ore they're getting is.

00:12:02 If they're producing specialty metals,

00:12:04 they have to know if they're getting the right proportions and the necessary uniformity in their alloys.

00:12:10 On the other hand, the users of those products have to check to see that they've got the proper materials for the job.

00:12:16 This is true especially of equipment and engineering companies and power utilities.

00:12:21 Let's see.

00:12:22 So far, we're talking about raw materials and the products of basic industries.

00:12:27 And more.

00:12:28 For instance, because the Portaspec can analyze so many elements,

00:12:32 it's quickly becoming popular in the plastics industry.

00:12:34 But that's still a basic industry, isn't it?

00:12:37 Right.

00:12:38 Now, in manufacturing, the information it can provide is important in another way.

00:12:42 If you know what's in a coating on some substrate,

00:12:44 then by measuring the concentration of the coating material, you can determine...

00:12:48 How thick it is.

00:12:49 Absolutely.

00:12:50 So you can measure the thickness of chrome coatings on metals...

00:12:53 For automobile parts.

00:12:55 Or aluminum cans.

00:12:56 Or what does iron oxide on plastic film sound like?

00:12:59 Sound like...

00:13:00 Oh, recording tape.

00:13:02 And more.

00:13:03 Computers.

00:13:04 This is really exciting.

00:13:05 The Portaspec can analyze all kinds of magnetic oxide coatings

00:13:09 for data or memory storage on tape, disc packs, or drums.

00:13:13 For those big data processing centers, right?

00:13:15 Yeah.

00:13:16 But for pocket calculators, too.

00:13:18 In fact, everything from coatings of semiconductor on substrates for microelectronic circuits

00:13:24 to gold on copper for printed circuit cards.

00:13:27 For the entire electronics industry.

00:13:29 Right.

00:13:30 But is this an exclusively industrial process?

00:13:33 Well, it's frequently an industrial process.

00:13:36 But the Portaspec is found in scientific laboratories, too,

00:13:39 including the research and development labs of a lot of major corporations.

00:13:44 And you're on your way to one of those right now.

00:13:47 Not exactly.

00:13:48 Not right away.

00:13:50 You know, there are new uses for portable, non-destructive analysis being found daily.

00:13:55 This Pitchford Scientific Portaspec is going into the field to do those jobs.

00:14:00 And I guess I'm going along.

00:14:02 Because every day, the field gets bigger.

00:14:06 And the future is out there, waiting to be analyzed.