This collection, digitized here in its entirety, consists of photographs depicting the facilities, machinery, and operations of the Aeronautical Materials Laboratory, part of the Naval Air Material Center located in Philadelphia, Pennsylvania. The photographs document the production and testing of assorted plastics, rubbers, coatings, and primers used in the construction of naval aircraft, with an emphasis on machinery used to evaluate the effects of weathering and various environmental conditions. The majority of photographs are drawn from a 1949 report on compounding rubber, though the entire collection spans 1949 to 1968. The photographs were collected by J. (Joseph) Hartley Bowen, Jr., who served as the Supervisory Chemist at the Aeronautical Materials Laboratory during this period.

-

Aeronautical Materials Laboratory staff

Box 1- 1961-Jun-02

Group photograph of Aeronautical Materials Laboratory staff members (from left) J. Hartley Bowen, Jr. (Technical Director); Martin J. Devine; and E. Robert Lamson. Assorted machinery, as well as a sign for the…

-

Aeronautical Materials Laboratory test site trailer

Box 1- Circa 1966

Three chemists from the Naval Air Engineering Center (Philadelphia, Pa.) posed in front of the Aeronautical Materials Laboratory test site trailer bound for Florida. The chemists are identified as follows (from left):…

-

Autoclave at the Aeronautical Materials Laboratory

Box 1- 1950s – circa

General view of an autoclave, used for the fabrication of plastics, at the Naval Air Engineering Center's Aeronautical Materials Laboratory. In the foreground, Laboratory Technical Director J. Hartley Bowen, Jr.…

-

Award presentation in honor of George B. Cook

Box 1- Circa 1963

Award presentation in honor of George B. Cook, the first chemist to join the Naval Aircraft factory in 1922. The individuals in the photograph are identified as follows (from left): Jack Smith (Laboratory Supervisor);…

-

Award presentation in honor of Sally J. Ketcham

Box 1- Circa 1965

Award ceremony in honor of Sally J. Ketcham, Metallurgist at the Naval Air Engineering Center located in Johnsville, Pennsylvania. The individuals in the photograph are identified as follows (from left): J. Hartley…

-

Banbury Mixer in the Rubber Compounding and Processing Laboratory

Box 1- Circa 1949

View of the Banbury Mixer used in the Rubber Compounding and Processing Laboratory at the Naval Air Experimental Station. The mixer is a Farrel-Birmingham Co. size B Banbury Mixer with a 25 H.P. motor and four-speed…

-

Banbury charging operation

Box 1- Circa 1949

View of a worker inserting rubber stock into the Banbury Mixer at the Naval Air Experimental Station's Rubber Compounding and Processing Laboratory. At the laboratory, the mixer was used to break down and mix rubber…

-

Building 537, Hangar and Laboratory facilities

Box 1- Circa 1950

Exterior view of building 537 at the Naval Air Material Center's Aeronautical Materials Laboratory, housing an aircraft hangar and laboratory facilities.

- Creator Of Work Naval Air Material Center, United States. Navy

- Subject Aerospace Research Laboratories (U.S.), Naval Research Laboratory (U.S.)

-

Calender sheeting operation

Box 1- Circa 1949

View of two engineers, Stanley Bilker (background) and Ralph Harper (foreground), operating the calender sheeting machine at the the Naval Air Experimental Station's Rubber Compounding and Processing Laboratory. The…

-

Closing operation on hydraulic press

Box 1- Circa 1949

View of a worker closing the hydraulic press in the Rubber Compounding and Processing Laboratory at the Naval Air Experimental Station. This unit is a 200-ton capacity Williams-White Moline machine equipped with three…

-

Colloid Mill

Box 1- Circa 1949

Charlotte experimental colloid mill used in the Naval Air Experimental Station's Latex and Chemical Laboratory for the preparation of finely divided dispersions and emulsions. This photograph was included in a 1949…

- Creator Of Work Naval Air Experimental Station, United States. Navy

- Subject Colloids, Scientific apparatus and instruments

-

Cutting operation for cross blending of ingredients

Box 1- Circa 1949

View of a worker cutting rubber stock from the mixing mill at the Naval Air Experimental Station's Rubber Compounding and Processing Laboratory. At the laboratory, the mill was used to mix rubber stocks or warm mixed…

-

Dumping of mixed stock from Banbury Mixer

Box 1- Circa 1949

View of a worker dumping mixed rubber stock from the Banbury Mixer at the Naval Air Experimental Station's Rubber Compounding and Processing Laboratory. At the laboratory, the mixer was used to break down and mix rubber…

-

Dynamic Test Laboratory at the Naval Air Experimental Station

Box 1- Circa 1949

General view of the Dynamic Test Laboratory at the Naval Air Experimental Station showing forced vibration machines and other equipment used to test rubber articles produced at the Station under simulated service…

-

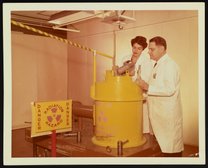

Eleanor Vadala and C.A. Cassola working with radioactive material at Aeronautical Materials Laboratory

Box 1- 1959-Dec-10

Color photograph of Eleanor Vadala, Chemist, and C.A. Cassola, Division Superintendent, working with a barrel of radioactive material at the Naval Air Material Center's Aeronautical Materials Laboratory. Ms. Vadala…

- Creator Of Work United States. Navy, Naval Air Engineering Center (U.S.)

- Subject Women in science, Aerospace Research Laboratories (U.S.), Employees, Scientific apparatus and instruments, Radiation, Women employees, Naval Air Engineering Center (U.S.), Women chemists, Chemists, Vadala, Eleanor, 1923-

-

Eleanor Vadala and Dr. Earl Hayes at the Naval Air Material Center

Box 1- 1959-Mar-19

Eleanor Vadala, chemist, and Dr. Earl Hayes, U.S. Defense Department, examining a display of airship fabric produced at the Naval Air Material Center. Ms. Vadala demonstrates the threads on an airship model while Dr.…

-

Eleanor Vadala with Gammacell 220 at the Naval Air Material Center

Box 1- Circa 1958

Eleanor Vadala, chemist, demonstrating use of the Gammacell 220, a textile chemistry machine, at the Naval Air Material Center's Aerospace Materials Laboratory. The Gammacell 220 is a source of Cobalt-60 gamma…

- Addressee Naval Air Engineering Center (U.S.)

- Creator Of Work United States. Navy

- Subject Women in science, Aerospace Research Laboratories (U.S.), Employees, Textile machinery, Radiation, Machinery, Naval Air Engineering Center (U.S.), Cobalt--Isotopes, Women employees, Women chemists, Chemists, Vadala, Eleanor, 1923-

-

Electrical Evaluation, Polymeric Materials

Box 1- 1958

View of two technicians using assorted apparatus to evaluate the electrical resistivity of high polymers at the Naval Air Material Center's Aeronautical Materials Laboratory. At the laboratory, assorted equipment was…

-

Electronically controlled constant rate of load tensile machine

Box 1- Circa 1949

General view of an electronically-controlled constant rate of load tensile machine used in the Naval Air Experimental Station's Physical Properties Laboratory. Tensile machines are commonly used to subject materials…

-

Endurance testing of aircraft hydraulic pump

Box 1- 1958

General view of machinery used to conduct endurance tests of high-temperature (400 degrees Fahrenheit), high-pressure (3000psi) aircraft hydraulic pump at the Naval Air Material Center's Aeronautical Materials…

-

Engineer operating shot peening equipment

Box 1- Circa 1958

General view of an engineer operating shot peening equipment at the Naval Air Material Center's Aeronautical Materials Laboratory. Shot peening is a cold work process used to finish metal parts to prevent fatigue and…

-

Engineers calendering experimental stocks of rubber

Box 1- Circa 1949

View of two engineers, Stanley Bilker (background) and Ralph Harper (foreground), operating the calender sheeting machine at the the Naval Air Experimental Station's Rubber Compounding and Processing Laboratory. The…

-

Establishment of constant humidity condition for the evaluation of experimental humidity indicators

Box 1- 1958

View of a technician at the Naval Air Material Center's Aeronautical Materials Laboratory using an unidentified apparatus to create a constant humidity condition in order to evaluate experimental humidity indicators. At…

-

Evaluation of experimental hydraulic fluids in simulated aircraft system

Box 1- 1958

General view of the simulated aircraft system at the Naval Air Material Center's Aeronautical Materials Laboratory used to evaluate experimental hydraulic fluids. A worker is seen seated in the foreground examining…

-

Evaluation of test panels coated with preservative oils after exposure in an experimental humidity cabinet

Box 1- 1952

General view of a technician making notes regarding the testing of panels coated with preservative oils after exposure in an experimental humidity cabinet at the Naval Air Material Center's Aeronautical Materials…